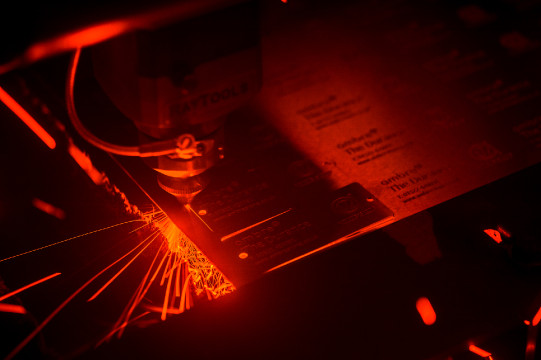

Introducing Laser Engraving and Cutting, a process of using lasers to engrave and cut an object or material. We use Co2/Fibre/Galvo CNC laser engraving for both engraving and for cutting. Laser can achieve much finer marking and cutting than other processes such as CNC milling.

What is Laser Engraving?

Laser Engraving at Brunel Engraving, using the very latest technologically advanced Epilog computer controlled two dimensional flat bed engraving machines can engrave metals, wood, rubber, glass and plastics (including Perspex) as well as natural materials such as slate, marble and granite.

Laser Engraving can be combined with our laser cutting service to offer high quality control panels cut to bespoke shapes. Find out more about this process below.

How does Laser Engraving work?

A laser will either vaporise the material at which it is pointed or it will change the material surface to create a contrast, depending on the type of laser used. By managing the output power of the laser, its pulse rate and the speed the laser moves over the surface, the cutting or engraving effect can be precisely controlled for each specific material and by reducing the power to a minimum, very thin materials can be engraved or cut.

In instances where the laser cannot remove the surface of a particular material, a chemical layer is initially sprayed onto the material surface which fixes on to the material when the laser is applied. The excess spray is then rinsed off to leave a permanent black image on the surface.

What is Laser Cutting?

Lasers are used for many purposes. They are used is for cutting metals and plastic plates. The laser cutting process is highly accurate, yields excellent cut quality, has a very small cutting width and small heat affect zone this makes it possible to cut very intricate shapes and small holes.

How does Laser Cutting work?

The laser beam is a column of very high intensity light, that is focused onto the plate. The focused laser beam goes through the bore of a nozzle right before it hits the plate. The beam has to be precisely focused so that the shape of the focus spot and the density of the energy in that spot are perfectly round and consistent and centered in the nozzle. The high power density results in rapid heating, melting and partial or complete vaporizing of the material. On a CNC laser cutter, the laser cutting head is moved over the plate in the shape of the desired part, thus cutting the part out of the plate.