|  |

Aluminium printing offers a versatile solution for various applications ranging from industrial labelling to decorative items. Two prominent methods for printing on aluminium surfaces are Anodic Printing and Dye Sublimation. While both methods offer durable finishes on aluminium, they employ different processes and have distinct capabilities. Let's delve into a comparative analysis of these two techniques:

Anodic Printing:

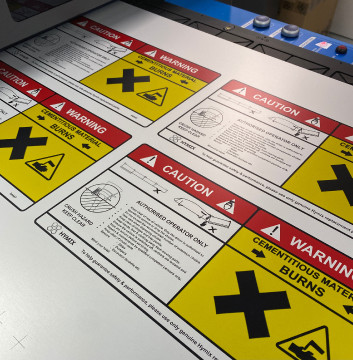

Anodic Printing, also known as Ano Printing or Ano Marking, involves printing directly into the surface of aluminium sheets. The process results in a robust finish that is resistant to scratches and solvents, making it suitable for applications requiring durability such as serial plates, labelling, and even control panels.

Process:

Printing: Ink is directly printed into the open pores of the aluminium surface.

Sealing: The printed aluminium undergoes a sealing process in a hot water bath at high temperatures. This step effectively seals the pores, encapsulating the ink and ensuring a high-quality, long-lasting print.

Capabilities:

Full-Colour Printing: Brunel Engraving utilise a flatbed digital printer over a screen-printing method, allowing for full-colour and photographic prints, offering versatility in design and without the need for multiple screens.

Durability: The sealed pores and scratch-resistant finish make Anodic Printing ideal for harsh environments and applications requiring long-term durability.

Dye Sublimation:

Dye Sublimation is a chemical process where solid ink on special paper is transferred onto a polyester-coated material using heat and pressure. This method provides vibrant colours and a smooth, durable finish.

Process:

Printing: Graphics / Content is printed onto special paper using an inkjet printer.

Transfer: The printed image is transferred onto a polyester-coated aluminium surface using heat (typically around 200 degrees Celsius) and pressure.

Bonding: During the sublimation process, the inks transfer at molecular level into the coating on the material, resulting in a seamless and durable finish.

Capabilities:

Vibrant Colours: Dye Sublimation offers the ability to produce stunning and vibrant colours, making it suitable for applications where aesthetics are crucial.

Versatility: With a range of material colours, Dye Sublimation can be used for various products such as nameplates, plaques, signs and industrial labels, providing flexibility in design and application.

|  |

Comparative Analysis:

Durability:

Anodic Printing: Offers a highly durable finish with scratch and solvent resistance, making it suitable for tough environments. Additionally, Anodic Printing is available in thicker aluminium sheets, we stock thicknesses from 1mm to 3mm, enhancing its durability and resilience to impact.

Dye Sublimation: Provides a durable finish; however, the substrate used for Dye Sublimation is typically around 0.5mm thick. While the finish is resilient, the thinner material may be more susceptible to dents or bending, especially in high-impact environments.

Colour Quality:

Anodic Printing: Capable of full-colour and photographic prints, which ensures excellent colour reproduction. However, Anodic Printing is limited to the satin silver colour of the aluminium material, which may affect the final appearance of the print.

Dye Sublimation: Known for its vibrant and vivid colours, making it ideal for applications where colour quality is paramount. Dye Sublimation offers a selection of colours and finishes, providing greater versatility in design. Additionally, Dye Sublimation allows for the option of a white backing, enhancing colour vibrancy and opacity, which is not available in Anodic Printing.

Versatility:

Anodic Printing: Suited for applications such as serial plates, labelling, and control panels, particularly in industrial settings.

Dye Sublimation: Versatile and can be used for a wide range of products including signage, nameplates, plaques, and industrial labels, offering flexibility in design and application. Often seen as an excellent cost-effective solution to screen printing.

In conclusion, both Anodic Printing and Dye Sublimation offer unique advantages depending on the specific requirements of the application. While Anodic Printing excels in durability and suitability for harsher industrial environments, Dye Sublimation stands out for its vibrant colours and versatility across various products. Understanding the strengths of each method is crucial in selecting the most suitable printing technique for your specific needs.

Reach out to our sales team and discover how our Anodic Printing and Dye Sublimation services can enhance your brand's presence. Let's elevate your products with durability and vibrant colours. Contact us today for a quotation