|  |

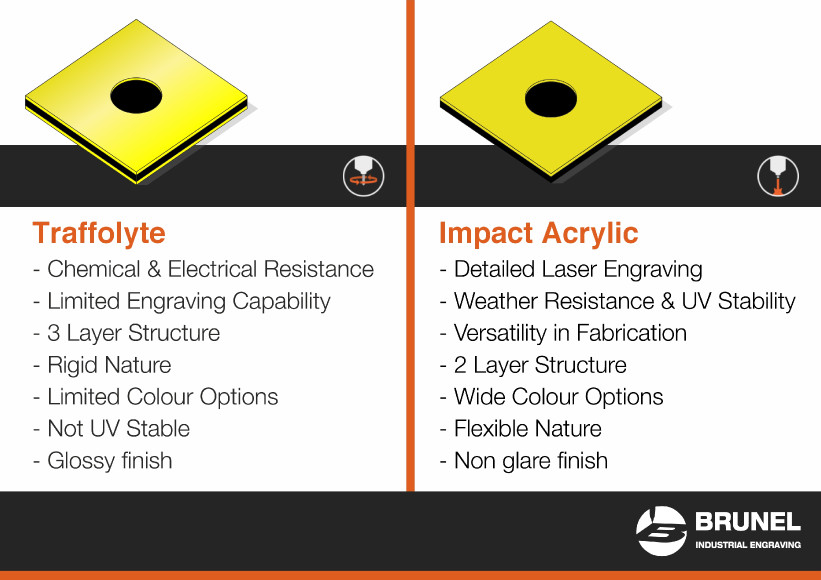

At Brunel Industrial Engraving we are constantly asked about the difference between the two materials, whilst traffolyte has been around for many years and seems to remain as the popular choice for labels, impact acrylic is quickly catching up and offers its own benefits to many industry types.

Both materials offer distinct advantages, catering to different needs and preferences. In this blog post, we delve into the characteristics, applications, and comparative aspects of Traffolyte and Impact Acrylic to help you make an informed decision for your specific requirements.

Traffolyte:

Traffolyte, a phenolic engraving laminate, also sometimes known as Traff, Traffolite, ABET Rigid Laminate or Hard Laminate is a versatile material widely used for industrial labelling and signage. Here are some key features:

Chemical & Electrical Resistance: Traffolyte exhibits high resistance to chemicals, ensuring longevity even in chemically aggressive environments. It is also very good at electrical insulation making it a trusted choice for electrical control & panel labels

Engraving Capability: There are some limitations when producing small details as we CNC Rotary engrave our Traffolyte. However this 3 ply material offers great versatility and can be easily engraved on both sides, which is often crucial for identification tags and signage.

Layer Structure: With its three or more layers, Traffolyte offers enhanced durability and engraving capabilities.

Rigid Nature: Traffolyte is a rigid material, however, it is susceptible to delaminating in harsher conditions and will snap when bent.

Colour Options: Available in a limited range of standard colours, Traffolyte offers flexibility in design and customization.

Glossy Finish: Traffolyte typically has a glossy finish, adding to its aesthetic appeal and visibility.

Not UV Stable: Traffolyte is often known to be an exterior grade material but whilst demonstrates some resistance to UV radiation, the colour and structural integrity can be affected when exposed to exterior conditions over time resulting in the material to de-laminate.

Applications:

Impact Acrylic:

Impact Acrylic, also referred to as Rowmark™ or Gravoply™, is a often supplied as a two layer laminate (3 -ply is available in some colour options) renowned for impact resistance & UV stability. Let's explore its notable characteristics:

Detailed Engraving: Brunel Engraving use Co2 lasers to engrave impact acrylic, this allows for a much more detailed / finer engraving, which is critical when reproducing items such as barcodes, QR codes and small lettering.

Weather Resistance: It exhibits excellent weather resistance & UV stability, making it suitable for both indoor and outdoor applications. Impact acrylic will not delaminate.

Versatility: Impact acrylic can be easily fabricated and machined, allowing for a wide range of shapes and designs to be created.

Layer Structure: Impact acrylic typically has two layers, contributing to its strength and flexibility.

Colour Options: Available in a huge range of colours & finishes, Impact Acrylic offers flexibility in design and customisation.

Non-Glare Finish: Impact acrylic often features a non-glare finish, reducing reflections and glare for improved visibility in various lighting conditions.

Flexible Nature: Impact acrylic is a flexible laminate, capable of being heated up and folded, offering versatility in fabrication and installation.

Applications:

In conclusion, both Traffolyte and Impact Acrylic offer unique advantages and are suited for different applications. When selecting between the two, consider factors such as durability requirements, customisation needs, visual aesthetics, and budget constraints. Ultimately, the choice between Traffolyte and Impact Acrylic should align with your specific project requirements and objectives.

Contact the sales team to discuss and obtain a quotation for any of your labelling requirements

Please click the following links to access these material data sheets:

Traffolyte Data Sheet LaserMax Impact Acrylic Data Sheet Laserables II Impact Acrylic Data Sheet